Aeva's 4D Lidar Technology Transforms Manufacturing with Precision

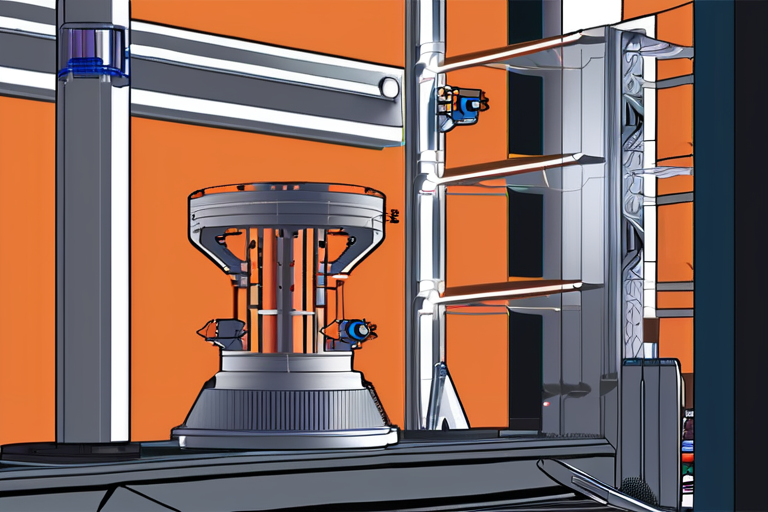

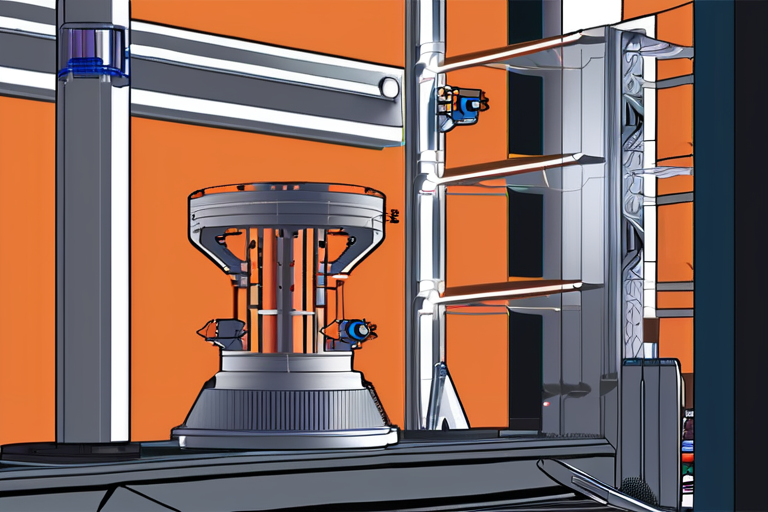

In a significant development for the manufacturing industry, Aeva has adapted its 4D lidar technology, originally designed for automotive applications, to bring precision and accuracy to factory floors. The company's noncontact motion sensor, Aevas, is now being used to monitor and control production processes in real-time.

According to Aeva's CEO, Soroush Salehian, "Our 4D lidar technology has been a game-changer for the automotive industry, and we're excited to bring its precision and accuracy to manufacturing. With Aevas, manufacturers can now achieve unprecedented levels of quality control and efficiency."

Aevas uses Aeva's patented 4D lidar technology to create high-resolution maps of objects and environments in real-time. This allows for precise tracking of moving parts and materials, enabling manufacturers to optimize production processes and reduce errors.

The adoption of Aevas in manufacturing is a significant milestone for the industry, which has long struggled with issues such as quality control, inventory management, and supply chain optimization. By leveraging Aeva's 4D lidar technology, manufacturers can now achieve unprecedented levels of precision and accuracy.

Aeva's decision to adapt its 4D lidar technology for manufacturing is a testament to the versatility and potential of this cutting-edge technology. "We're thrilled to see our technology being used in new and innovative ways," said Salehian. "Our goal is to make precision manufacturing accessible to all industries, and we believe Aevas is a major step towards achieving that goal."

The use of 4D lidar technology in manufacturing has significant implications for the industry as a whole. With its ability to provide real-time data on production processes, manufacturers can now optimize their workflows, reduce waste, and improve product quality.

Aeva's 4D lidar technology is not new to the market, having been used in automotive applications since 2020. However, its adaptation for manufacturing marks a significant expansion of its potential uses and applications.

As the industry continues to evolve and adopt new technologies, Aeva's Aevas system is poised to play a major role in shaping the future of precision manufacturing. With its ability to provide real-time data and precise tracking capabilities, Aevas has the potential to revolutionize the way manufacturers approach production processes.

In conclusion, Aeva's adaptation of its 4D lidar technology for manufacturing marks a significant milestone for the industry. As manufacturers continue to adopt this cutting-edge technology, we can expect to see unprecedented levels of precision and accuracy in production processes. With Aevas at the forefront, the future of manufacturing looks brighter than ever.

Background:

Aeva's 4D lidar technology was originally developed for automotive applications, where it has been used to improve safety features such as adaptive cruise control and lane departure warning systems. The company's patented technology uses a combination of radar and camera sensors to create high-resolution maps of objects and environments in real-time.

Implications:

The adoption of Aevas in manufacturing has significant implications for the industry as a whole. With its ability to provide real-time data on production processes, manufacturers can now optimize their workflows, reduce waste, and improve product quality.

Real-world applications:

Aeva's 4D lidar technology is being used in various industries, including automotive, aerospace, and consumer electronics. The company's Aevas system has been adopted by several major manufacturers, who are using it to improve production processes and achieve unprecedented levels of precision and accuracy.

Next developments:

As the industry continues to evolve and adopt new technologies, Aeva's Aevas system is poised to play a major role in shaping the future of precision manufacturing. With its ability to provide real-time data and precise tracking capabilities, Aevas has the potential to revolutionize the way manufacturers approach production processes.

*Reporting by Spectrum.*

Hoppi

Hoppi

Hoppi

Hoppi

Hoppi

Hoppi

Hoppi

Hoppi

Hoppi

Hoppi

Hoppi

Hoppi