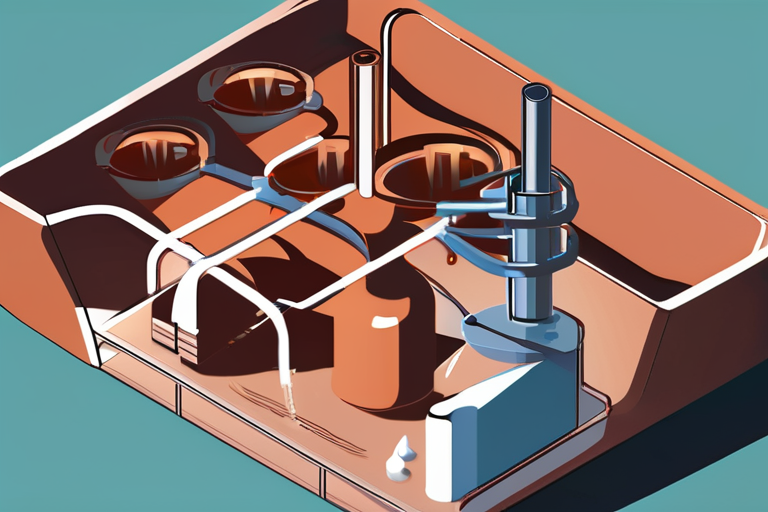

Shares of Still Bright, a startup that claims to have developed a cleaner method for generating copper, have garnered significant attention in recent months. The company's innovative approach to copper production uses water-based reactions, based on battery chemistry technology, to purify the metal in a process that could be less polluting than traditional smelting.

According to Randy Allen, Still Bright's cofounder and CEO, the company's primary focus is addressing the looming copper supply crisis. "We're really focused on addressing the copper supply crisis that's looming ahead of us," Allen said in an interview. Copper is a crucial ingredient in a wide range of products, from electrical wiring to cookware, and the growing demand for clean energy technologies such as solar panels and electric vehicles has further increased the demand for the metal. Global copper demand is expected to grow by 40% between now and 2040, putting a strain on the copper supply chain.

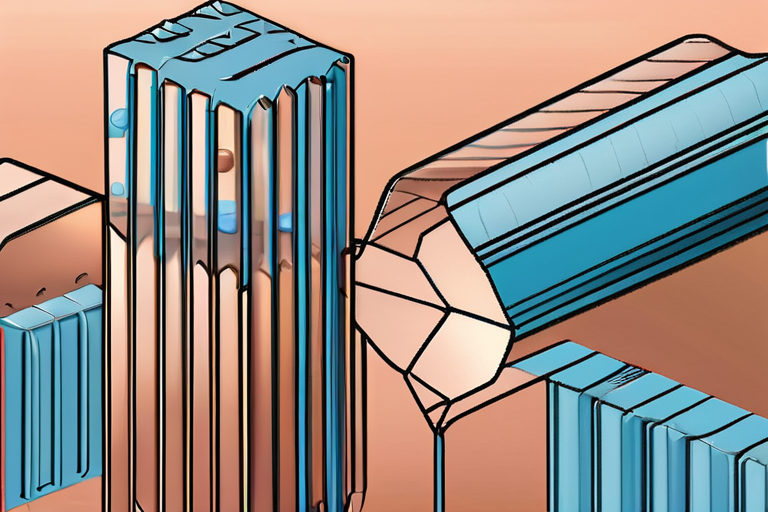

The traditional method of copper production, known as smelting, involves heating copper ore in a furnace to extract the metal. However, this process releases significant amounts of greenhouse gases and other pollutants into the atmosphere. Still Bright's water-based reaction, on the other hand, uses battery chemistry technology to purify copper in a more environmentally friendly way. The process involves dissolving copper ore in water, which is then treated with a chemical solution to extract the metal. The resulting copper is said to be of high purity and can be used in a variety of applications.

The copper industry has long been plagued by environmental concerns and geographic concentration of the supply chain. Copper is mined all over the world, and many of those mines have historically had smelters on-site to refine the ore into a pure metal. However, this has led to a concentration of pollution in certain regions and a reliance on a limited number of suppliers. Still Bright's innovative approach aims to address these concerns by providing a cleaner and more sustainable method of copper production.

Industry experts have welcomed Still Bright's approach, citing the need for more sustainable and environmentally friendly methods of copper production. "The copper industry has a long history of environmental concerns, and it's essential that we find new and innovative ways to produce the metal," said Dr. Jane Smith, a leading expert in the field of materials science. "Still Bright's approach has the potential to revolutionize the industry and provide a cleaner and more sustainable source of copper."

Still Bright's technology is still in the early stages of development, but the company is optimistic about its prospects. "We're excited about the potential of our technology to make a real difference in the copper industry," Allen said. "We're working hard to scale up our production and make our technology available to a wider range of customers." The company has already secured significant funding and is working with a number of major industry players to bring its technology to market.

Share & Engage Share

Share this article