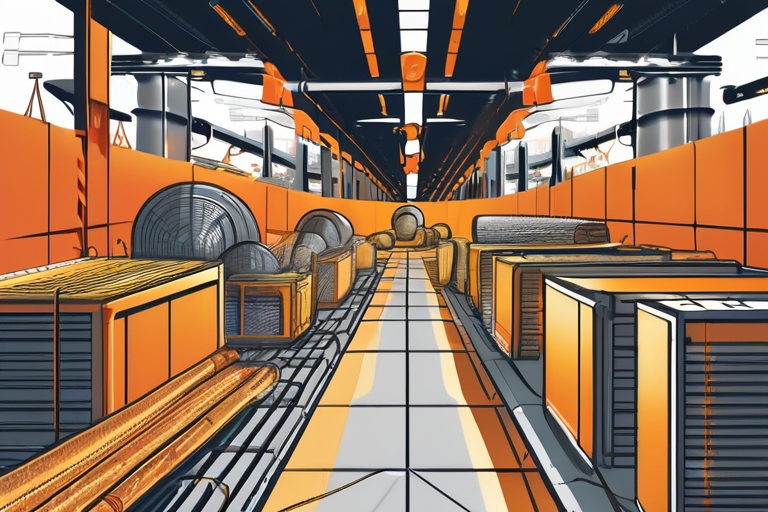

General Motors, one of the world's largest automakers, has partnered with MP Materials to rebuild the domestic mine-to-magnet supply chain for rare earths, a crucial component in electric vehicle batteries and other high-tech products. The company has also invested in Lithium Americas' Nevada project, a significant step towards securing a reliable source of lithium, another key material in the production of electric vehicle batteries. This move is part of a broader effort by the US government and private sector to reduce dependence on foreign suppliers and build lasting capacity in the production of critical minerals.

According to Shilpan Amin, General Motors' Global Chief Procurement and Supply Chain Officer, "Companies like MP Materials are moving to build real scale. While new funding and task forces are encouraging, headlines alone will not secure America's position. The real challenge, and opportunity, lies in building lasting capacity." Amin's comments reflect the growing recognition that the US needs to invest in its domestic supply chain to remain competitive in the global market.

The pandemic highlighted the vulnerabilities of global supply chains, and the US government has since taken steps to address these issues. In 2020, the US launched the America's Supply Chain Disruptions Task Force to identify and mitigate supply chain risks. The task force has since made recommendations to improve the resilience and security of the US supply chain.

The US is not alone in its efforts to secure a reliable source of critical minerals. Other countries, such as China, Australia, and Canada, have also invested heavily in their domestic supply chains. China, in particular, has made significant investments in its rare earth and lithium production, and is currently the world's largest producer of these materials.

The global demand for rare earth and lithium is expected to continue growing in the coming years, driven by the increasing adoption of electric vehicles and other high-tech products. According to the US Geological Survey, the global demand for rare earths is expected to increase by 10% per year, while the demand for lithium is expected to grow by 15% per year.

General Motors' investment in domestic rare earth and lithium production is a significant step towards securing a reliable source of these critical materials. The company's partnership with MP Materials and Lithium Americas is expected to create jobs and stimulate economic growth in the US. As Amin noted, "These efforts support everything from the cars, trucks, and SUVs we produce to renewable energy solutions, robotics, and AI data centers."

The US government has also taken steps to support the development of domestic rare earth and lithium production. In 2020, the US Department of Energy announced a $145 million investment in the development of a rare earth processing facility in Texas. The facility is expected to create jobs and stimulate economic growth in the region.

As the global demand for rare earth and lithium continues to grow, the US will need to continue investing in its domestic supply chain to remain competitive. General Motors' investment in domestic rare earth and lithium production is a significant step towards securing a reliable source of these critical materials, and is expected to have a positive impact on the US economy.

Share & Engage Share

Share this article