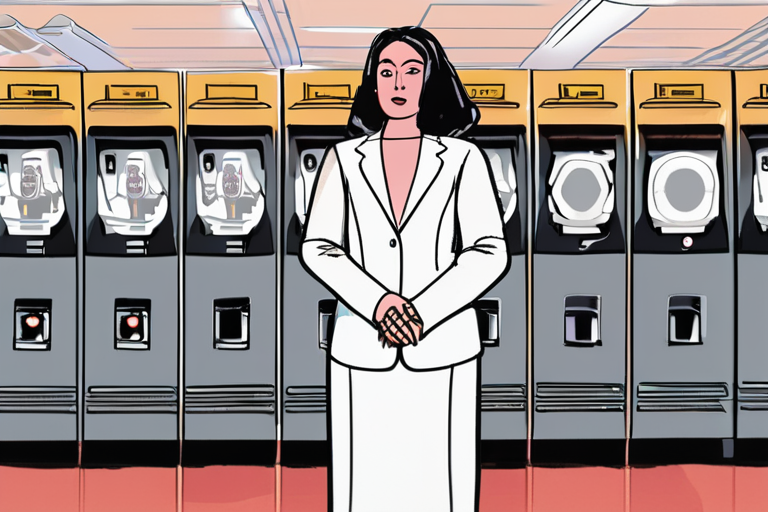

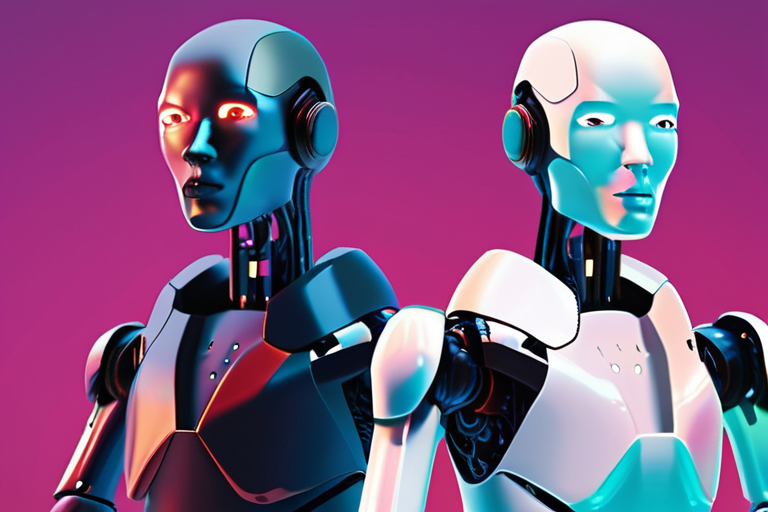

AgiBot, a Shanghai-based humanoid robotics company, has developed a system that enables two-armed robots to learn manufacturing tasks through human training and real-world practice on a factory production line. The company's innovative approach combines teleoperation and reinforcement learning to train the robots, which is being tested on a production line belonging to Longcheer Technology, a Chinese company that manufactures smartphones, VR headsets, and other electronic gadgets.

According to AgiBot, the system allows the robots to adapt to new tasks and environments through trial and error, mimicking the way humans learn. "Our goal is to create robots that can learn and adapt to new tasks in real-time, without the need for extensive programming," said an AgiBot spokesperson. "This technology has the potential to revolutionize the manufacturing industry by increasing productivity and efficiency."

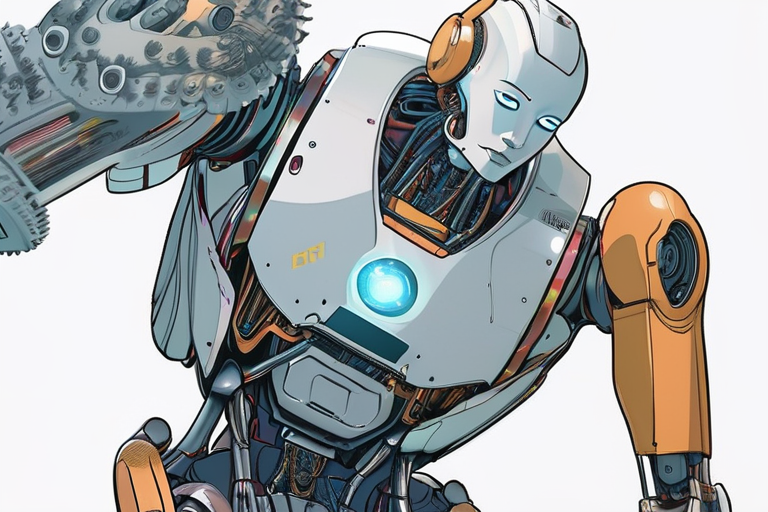

The use of robots in factories is not new, but the work involved in assembling complex products like smartphones requires dexterity, sensing, and adaptation, skills that robots generally lack. AgiBot's system addresses this limitation by allowing humans to train the robots through teleoperation, which enables the robots to learn from human demonstrations. The reinforcement learning aspect of the system allows the robots to refine their skills through trial and error, making them more efficient and accurate over time.

The testing of AgiBot's system on Longcheer Technology's production line is a significant milestone in the development of industrial robotics. "We are excited to see the potential of this technology to improve our manufacturing processes," said a Longcheer Technology spokesperson. "The ability to train robots to perform complex tasks in real-time could be a game-changer for our industry."

The impact of AgiBot's technology on the manufacturing industry is expected to be significant, with the potential to increase productivity and efficiency. However, it also raises concerns about job displacement, as robots may be able to perform tasks that were previously done by humans. "While it's true that some jobs may be displaced, new ones will be created in areas like robotics maintenance and programming," said an industry analyst.

AgiBot's technology is not limited to the manufacturing industry, and the company is exploring applications in other areas, such as logistics and healthcare. The company plans to continue testing and refining its system, with the goal of commercializing it in the near future. As the use of robots in factories continues to grow, AgiBot's innovative approach is likely to play a significant role in shaping the future of industrial robotics.

Share & Engage Share

Share this article