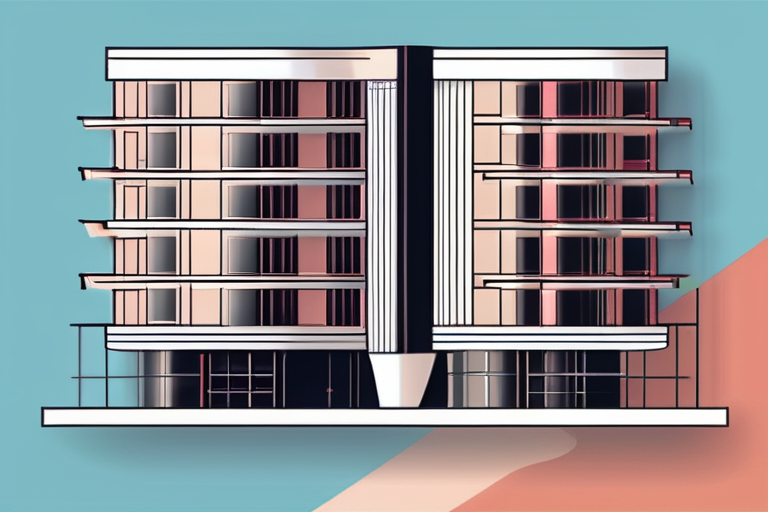

Researchers at the University of Tokyo and a U.S.-based structural engineer have developed a new computational form-finding method that could revolutionize the way architects and engineers design lightweight and free-form structures covering large spaces. The technique, which utilizes NURBS surfaces, a widely used surface representation format in computer-aided design (CAD), has drastically reduced computation costs, making it possible to complete tasks that previously took 90 hours on a high-end GPU in about 90 minutes on a standard CPU.

According to Dr. Masaaki Miki, the lead researcher from the University of Tokyo, "This breakthrough will enable architects to create more complex and creative gridshell designs, which have the potential to transform the way we build and design structures." Gridshells, thin, curved surfaces whose members form a networked grid, are a type of structure that has been gaining popularity in recent years due to their ability to cover large spaces while minimizing material usage.

The new method, which has been tested and validated through various simulations and experiments, makes use of a combination of NURBS surfaces and computational form-finding algorithms to generate optimal gridshell designs. This approach allows for the creation of complex curved surfaces that were previously difficult or impossible to achieve using traditional design methods.

The development of this new method has significant implications for the field of architecture and engineering. "The ability to design and build more complex and efficient gridshells will have a major impact on the way we design and construct buildings, bridges, and other structures," said Toby Mitchell, a structural engineer from the U.S. who collaborated with Dr. Miki on the project. "This technology will enable architects and engineers to push the boundaries of what is possible and create more innovative and sustainable designs."

The new method also has the potential to be applied to design-laminated timber gridshells, which are a type of structure that uses laminated wood to create a strong and lightweight gridshell. This approach has been made possible by advances in computer numerical control (CNC) fabrication technologies, which allow for the precise cutting and assembly of complex shapes.

The researchers behind this breakthrough are optimistic about the potential impact of their work. "We believe that this technology will have a major impact on the way we design and build structures in the future," said Dr. Miki. "We are excited to see how architects and engineers will use this technology to create innovative and sustainable designs."

As the field of architecture and engineering continues to evolve, it is likely that we will see more innovative and complex designs emerge. The development of this new computational form-finding method is just one example of the many advances that are being made in this field. As researchers continue to push the boundaries of what is possible, we can expect to see even more exciting developments in the future.

Share & Engage Share

Share this article