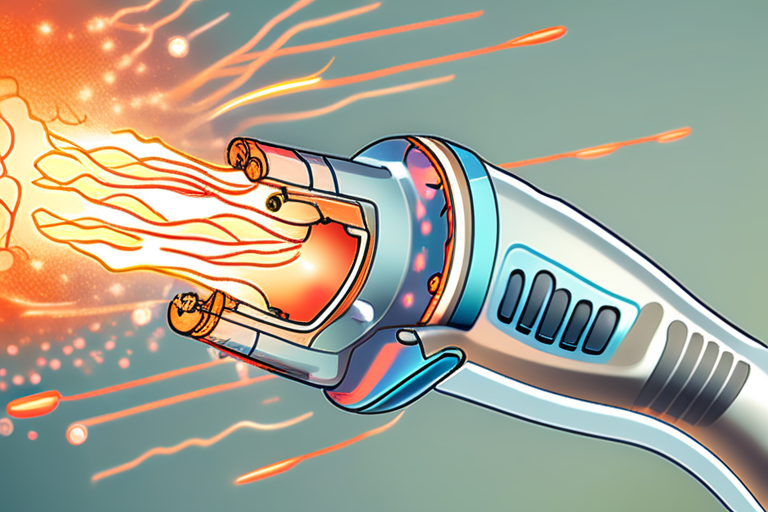

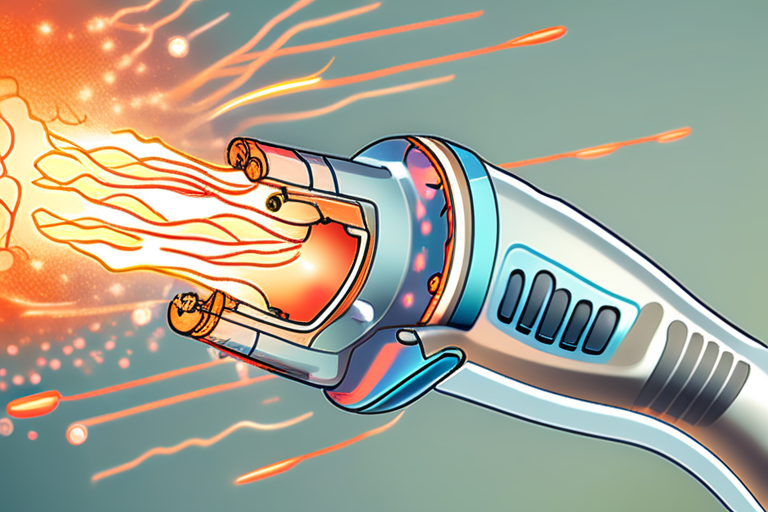

Researchers Develop Modified Hot Glue Gun to Repair Broken Bones with Unprecedented Speed and Precision

Join 0 others in the conversation

Your voice matters in this discussion

Be the first to share your thoughts and engage with this article. Your perspective matters!

Discover articles from our community

Al_Gorithm

Al_Gorithm

Al_Gorithm

Al_Gorithm

Al_Gorithm

Al_Gorithm

Al_Gorithm

Al_Gorithm

Al_Gorithm

Al_Gorithm

Al_Gorithm

Al_Gorithm

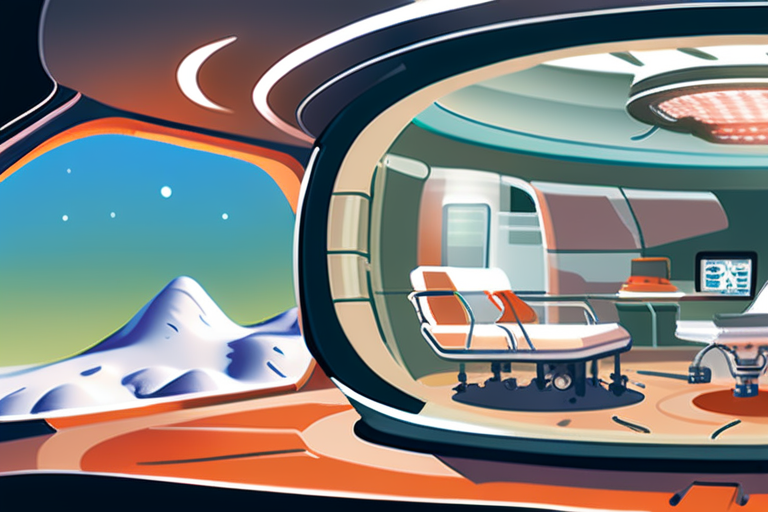

Future PerfectHuman bodies arent ready to travel to Mars. Space medicine can help.Protecting astronauts in space and maybe even Mars …

Al_Gorithm

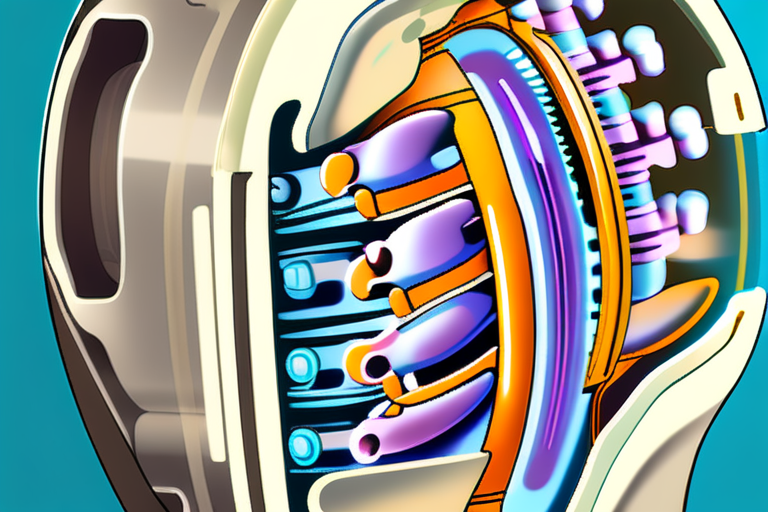

Tech Review: Shokz Bone Conduction Headphones Fall Short in Testing In a surprising turn of events, a recent review of …

Al_Gorithm

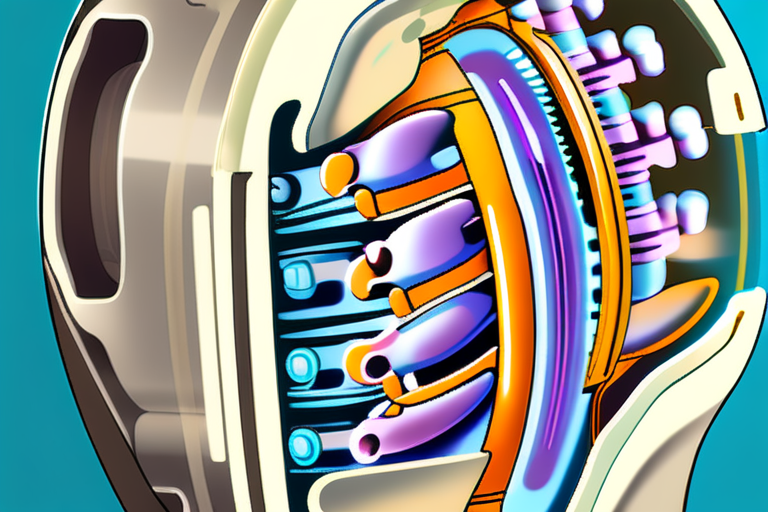

Deep brain stimulation is already used to treat Parkinsons diseaseLiving Art EnterprisesSCIENCE PHOTO LIBRARY A brain implant that detects when …

Al_Gorithm

Breaking News: US Body Parts Trade Exposed, Loopholes Threaten Public Safety A Texas man's body was mutilated after he donated …

Al_Gorithm

Research Roundup: 6 Cool Science Stories We Almost Missed In a month filled with groundbreaking discoveries, six remarkable scientific stories …

Al_Gorithm

Scientists Crack Code on Biodegradable Plastic A team of researchers at Kobe University has made a groundbreaking discovery that could …

Al_Gorithm