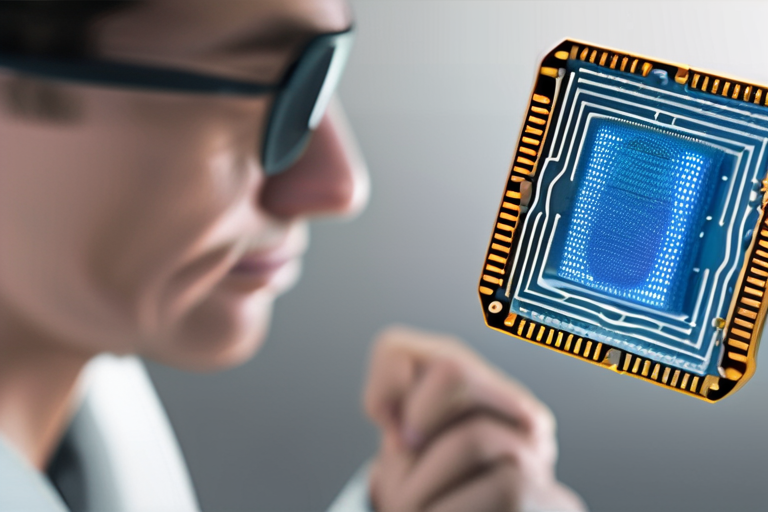

Researchers at Linköping and Lund universities in Sweden have successfully demonstrated a novel method for creating high-performance electronic electrodes using visible light and specially designed water-soluble monomers. This breakthrough technique allows conductive plastics to form directly on various surfaces, including glass, textiles, and living skin, paving the way for innovative electronic and medical applications.

According to Dr. Thor Balkhed, a researcher involved in the project, the method requires no advanced laser setups, and visible light from simple LED lamps, such as a party light, can drive the polymerization process. "I think this is something of a breakthrough," Dr. Balkhed said. "It's another way of creating conductive materials without the need for dangerous chemicals." The researchers' results show that these electrodes can be produced on a wide variety of surfaces, opening up new possibilities for electronics and medical sensing technologies.

The technique relies on the use of water-soluble monomers that can be triggered by visible light to form conductive plastics. This chemical-free approach eliminates the need for hazardous substances and reduces the complexity of the manufacturing process. The resulting electrodes have been shown to exhibit high performance and stability, making them suitable for a range of applications.

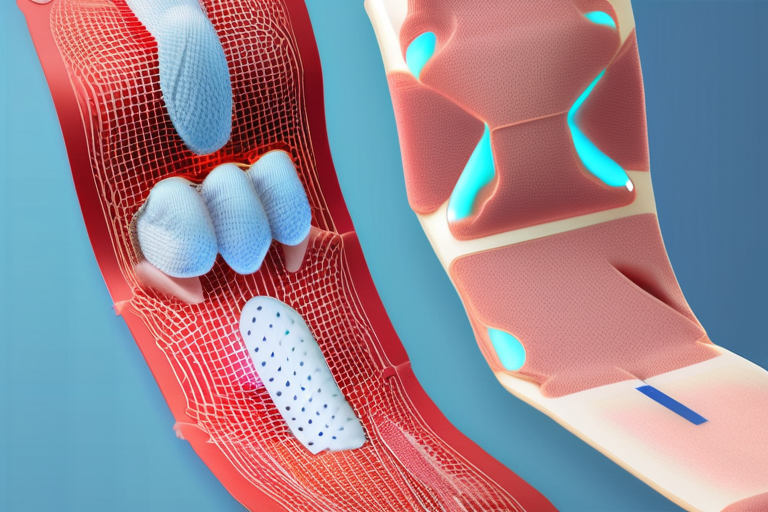

This development has significant implications for the electronics and medical industries. The ability to create conductive materials on various surfaces could enable the creation of wearable electronics, implantable devices, and other innovative technologies. Additionally, the use of visible light to trigger polymerization could simplify the manufacturing process and reduce costs.

The researchers' findings have been published in a recent study, which highlights the potential of this technique for creating high-performance electronic electrodes. As the field continues to evolve, it is likely that we will see the development of new products and applications that take advantage of this breakthrough technology.

The next steps for the researchers involve further optimizing the technique and exploring its potential applications. Dr. Balkhed and his team are currently working on refining the method and scaling up production to make it more viable for commercial use. As the technology continues to advance, we can expect to see a wide range of innovative products and applications emerge, transforming the way we interact with electronics and medical devices.

Share & Engage Share

Share this article